Welcome to

PRAKASH TECHNO PLAST INDIA PVT. LTD.

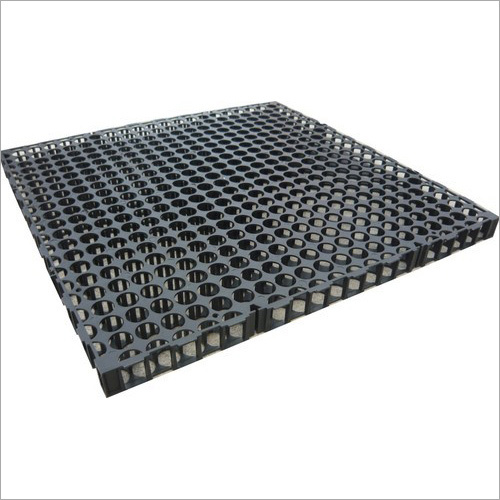

A reliable shop to get quality Plastic Injection Moulder, Plastic Drain Cell, HDPE Drainage Cell, Drainage Cell, Plastic Cable Tie, Plastic Grass Towers, etc.

Prakash Techno Plast India Pvt. Ltd., a 2010 established company is renowned today as a reliable manufacturer and exporter of Plastic Grass Paver and Water Treatment Parts of optimum quality. Grab Handles, Plastic Handle, Hydro Drain Cell, Polypropylene Pall Ring, Plastic Crate, Plastic Grass Paver and Drainage Cell are some of our products in our portfolio, that are highly demanded given to their rugged construction, low maintenance, crack resistance and low service life. Customers can opt industrial cases from PTP to safeguard products as well as promote brand. Latest technology is used in the products designing and fabrication processes, conducted at our highly advanced infrastructural facility.

Quality Focused Entity

Our ISO/TS (16949:2009) and ISO/TS (16949:2008) certified company is headquartered of our in Hosur, Tamil Nadu. This facility was set-up by Mr Prakash M. Valecha (MD), under the guidance and philosophy of the mentor and consultant, Sri Mohandas R Valecha. Since then, Mr. Prakash M. Valecha has been guiding personnel to reach new heights. At the facility, a team of knowledgeable personnel fabricate the range of plastic grass paver and water treatment parts in several specifications. All professionals work together to achieve shared goal and deliver each order within time. Around 20% of the products produced are supplied to the Thailand markets.

Every day, approx. 40 tons of plastic granulates are processed and over 4 million plastic cases are produced every year.

Working Culture

Prakash Techno Plast (PTP) is become a famous business entity by helping people of all the sectors with its creations like Softener Strainer, Plastic Pall Ring, Plastic Grass Paver,Plastic Drainage Cells, Drainage Cells, etc., from the past 50 years. We started with a small factory in South India (HOSUR -TN) and with years, we have growth tremendously, credit of which goes to product line expansion, product innovation and our commitment to serve customers across the globe. In our premise, there is a healthy work culture, employees are motivated and they support each other to meet clients' demands.

Clientele

What other companies of our business dreams for is what we have, a huge clientele of most famous names of the market. We are proud of our achievements that have made us secure our place in hearts of numerous clients, some of the famous names are:

|

Tier I Customers |

Tier II Customers |

OEM Customers |

|

|

|

Our Infrastructure

It is not possible for our company to efficiently design & develop

Plastic Cable Tie, Drainage Cell, Grab Handles, Air Filter Housing and other allied products, without the support of maintained

infrastructure facilities. Our investors have heavily invested on constructing a modern

infrastructure, which is spacious, beauty from interior & exterior

and has many facilities. The company has maintained Clean Room Facility

for Manufacturing as well as Sub Assembly of Water Purifier.

Manufacturing Facilities

We have an architecturally built manufacturing division, equipped with fully automatic C.N.C based micro processor injection moulding machines, which ranges from 50 tons to 1000 tons. The machine updated in premise of renowned brands like Negri Bossi, Feromatic Millacron, Demag etc. These machines are maintained as they help in producing components of various range from 1 gm to 5000 gm. We also have blow moulding machine, range of which varies from 1 ltr to 20 litrs (up to 2000 gm) to have efficiency in completion of works and ability to meet clients' demands.

In this set up, several engineering material including

Polyacetals, Polyurethane, Polyamide (Nylon 6, 6.6) Polycarbonate, Glass

filled & mineral filled ABS, Polyethylene & Polypropylene and

PP, Nylons are being molded and utilized for making several components

& parts. Further, the set up comprises in-house tool room with

facilities such as radial drill machine, tool post grinders, tool

grinders, pantograph, deckle milling machine and 3 lathe machines which

can hold upto 1000 mm job. These are maintained to easily produce moulds

of any kind in a good speed and then fulfill clients' demands.

Our Team

When

there are talented people in a team who work together tremendously then getting outstanding results become obvious. And we are

fortunate to have such people, who are role model of many industry

experts. The leading team of our company is of people who are

intelligent, honest, professional and punctual, they with their guidance

& business decisions make us stand among the top companies of the

market. Following are the experts who guide us:

- Sri Mohandas R. Valecha, Chairman & Mentor

- Prakash M Valecha, Managing Director

- Jeetendra Valecha, Co. Managing Director

Working Culture

Prakash Techno Plast (PTP) has established itself a famous business entity, the company has been helping people of all the industries with its creations, from past 50 years.Our Infrastructure

It wouldn't have been possible for us to smoothly develop & serve Plastic Cable Tie, Grab Handles, Drainage Cell, Air Filter Housing and many such industrial productOur Team

When there are people in a team that are taken as an inspiration across the industry then getting amazing results become obvious.Quality Policy

As serving quality HDPE Drainage Cell, Plastic Drain Cell, Grab Handles, Plastic Cable Tie, Blow Moulded Components and all the products is our priority, to ensure this, we are following a strict quality control policy. The policy is being prepared by the experts of the industry and it incorporates the following:- Attaining complete satisfaction of the clients with quality products, personalized services and and prompt products delivery.

- Have regular improvement in the Quality Management System.

- Regularly communicate across the organization about the policy and its changes so that improvements can be done.

-

Plastic Drainage Cells -

Hydro Drainage Cell -

Plastic Grass Interlocking Pavers -

Interlocking Plastic Grass Paver -

Cable Ties -

Nylon Cable Tie -

Grab Handles -

Automotive Grab Handles -

PP Water Strainer For Softener -

Sp 15 Strainer -

Plastic Headlamp Cover -

Headlamp Plastic Cover -

Polypropylene Pall Ring -

Plastic Pall Ring -

Air Filter Housing -

Industrial Plastic Molded Components -

ABS Union -

Water Filtration Distribution Components -

Plastic Water Distribution System -

Pre Filter Housings -

Distribution System -

In out Plastic Adaptor -

Adaptor in out for Carbon Filter -

Extra Long Strainer -

Plastic Strainers -

Slot Type Strainer -

Slot Type Filter Strainer -

Filter Candle Cartridge -

Softener HDPE Bottle -

Ring Type Plastic Strainers -

Slot Type Plastic Strainers -

Sewage Treatment Equipment -

Water Treatment Spare Parts -

Self Locking Cable Tie -

Releasable Cable Tie -

PLASTIC Interlocking Pavers

|

PRAKASH TECHNO PLAST INDIA PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |